PBV Series Plastic Ball Valves

Industrial Specialties Mfg. offers the complete line of the PBV Series Ball Valves. With 4 body materials, 3 seal materials and multiple end connections, the PBV Series has what you need for your application. Available with or without panel mount thread.

Industrial Specialties Mfg. offers the complete line of the PBV Series Ball Valves. With 4 body materials, 3 seal materials and multiple end connections, the PBV Series has what you need for your application. Available with or without panel mount thread.

Materials include:

Kynar

Nylon

PVC

Polypropylene

Seal Materials include:

Buna-N

EPDM

Viton

Connections include:

1/8" Male and Female NPT

1/4" Male and Female NPT

1/8", 1/4", 5/16", 3/8" and 1/2" Hose Barbs

If one of our standard products does not meet your needs, our team of experts will work with your engineers to build a fitting to your specifications. All products are produced and typically shipped directly from us to the end user, saving both time and expense.

For whatever your miniature pneumatic, vacuum and fluid circuitry components needs, Industrial Specialties Mfg. will provide the best fit for your application.

Contact one of our experienced professionals today to discuss the solution that's right for you!

Industrial Specialties Mfg.

4091 S. Eliot St.

Englewood, CO 80110

Phone: 303-781-8486

Fax: 303-761-7939

An ISO 9001:2008 Certified Company

|

|

Versatile, Multi-Pin Molded Connectors For Sensors & Automation

Canfield Connectorrs M8 and M12 multi- pin molded connector series for sensors

Canfield Connectorrs M8 and M12 multi- pin molded connector series for sensors

and automation offers the highest quality standards and an affordable price. The

industry standard M8, Pico, straight locking connector is available with either 3

or 4 poles, has a nominal voltage rating of 120 V AC/DC, a current rating of 4

amps and 24 AWG wire gauge. The M12, Micro, is available as either a straight

or 900 locking connector with 3, 4, or 5 poles. The 3 and 4 pole versions have

a nominal voltage rating of 240 V AC/DC and a 4 amp current rating while the 5

pole is rated 120 V AC/DC with a 3 amp current rating. Both the M8 and the

M12 have a nylon housing, black PUR or PVC cable, are IP67 environmentally

resistant and have a temperature rating of -255 to +855C.

Canfield Connector is certified to ISO 9001 with design and the M8 and M12

Series is proudly manufactured and 100% tested in the USA. Complete

specifications can be found at www.canfieldconnector.com

Canfield Connector

8510 Foxwood Court

Youngstown, Ohio 44514

Tel: (330) 758-8299

Fax: (330) 758-8912

|

|

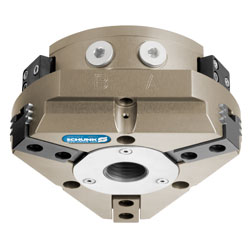

New sizes for the PEH Long-Stroke Servo-Electric Gripper

SCHUNK has expanded its servo-electric 2-finger parallel gripper of the PEH

SCHUNK has expanded its servo-electric 2-finger parallel gripper of the PEH

series to include sizes 30 and 50. This once again significantly expands the

application spectrum for this universal long-stroke gripper, because with a

maximum stroke of 100 millimeters per finger for the PEH 50, these grippers

are now suitable for a large parts spectrum, extending from small components

to large workpieces. The robust guides are designed for precise handling even

at high loads and the gripping force can be adapted to the broad application

spectrum for the PEH 50 as high as 1400 N, with maximum finger lengths

of up to 250 millimeters.

The PEH grippers are driven by a brushless servo motor, which transfers its

power directly to the ball bearing drive spindle. The base jaws are moved by

a driver on the spindle, while a kinematic unit synchronizes the movements

of the two base jaws based on the rack and pinion principle, which ensures

exact centric gripping with a repeat accuracy of 0.05 mm.

With the new SCHUK controller, the complete control and power electronics

are already integrated in the grippers of the PEH series. This controller is used

for the standardized control of almost all servo-electric components from the

SCHUNK product line and enables very easy programming, pre-configuration

and commissioning. Single commands can be combined to form complete tasks, and

command libraries that are once created can also be used for other modules.

Donnt miss out on what SCHUNK has to offer at IMTS 2010!

Visit us at Booth W-2000 for all your Automation needs.

About SCHUNK:

SCHUNK is a family owned operation and a global player in one. Totaling more than 60 years of

experience, SCHUNK is a leading worldwide manufacturer of toolholding components, workholding

systems, and automation components. With a reputation for high quality products, absolute

precision, and continuous innovation, SCHUNK is a reliable partner. For more information, visit

www.schunk.com

|

|

Economical, Modular Global Air Preparation from Parker Hannifin

Richland, Michigan Parker Hannifin announces the release of its Global Air

Richland, Michigan Parker Hannifin announces the release of its Global Air

Preparation System, an economical, modular solution for pneumatic

requirements. Using a patented, lightweight T-bracket/joiner assembly for

easy installation and mounting, the comprehensive Global Air Preparation

System offers full-featured filters, regulators, filter/regulators, and lubricators

available in three body sizes including the P31 Mini Series, the P32 Compact

Series and the P33 Standard Series. Each series is available with BSPP,

BSPT or NPT thread type requirements.

Parker Global Air Preparation products are affordable, allowing companies of all

sizes to create high performing pneumatic systems scaled to their needs,, says

Michael Nick, Product Sales Manager from Parker Hannifin. The components are

also versatile and modular, which means customers can add accessories such as

bulk liquid separators, electronic proportional regulators and driers to create complete dry air systems. This is an ideal solution for businesses who want the benefits of clean dry air to make their products and processes more competitive while managing costs..

The Parker Global Air Preparation System includes a wide range of options that allow companies to

meet their air preparation needs. Filters offer quick release bayonet-type integral bowl and bowl

guard assembly, multiple viewing slots on the bowl guard and a manual or auto drain option.

Regulators have easy to adjust non-rising knobs with snap-lock to prevent accidental change in

set pressure. Lubricators can be filled under pressure and offer a combination knob and sight-

dome for adjusting the precise amount of lubrication. Customers can easily assemble individual

units into various combinations using the patented modular lightweight body connectors.

Parker is a leader for comprehensive air preparation products,, says Nick. Now, with the

release of a modular global air preparation solution, customers worldwide have a reliable option

for streamlining their pneumatic supply chain with Parkerrs quality support and service..

With Parker's breadth of products, customers can also take advantage of complimentary valve and

actuator products, such as the Isys Micro Valves and Parker-Origa Rodless Cylinders, that

integrate with each of the P Series body sizes.

More information is available at www.parker.com/globalFRL

|

|

ROSS CONTROLS Introduces its High-Relief Pilot-Operated Regulator

(TROY, MI) ROSS CONTROLS is proud to announce the introduction of its

(TROY, MI) ROSS CONTROLS is proud to announce the introduction of its

High-Relief Pilot-Operated Regulator for high-flow applications. This multi-purpose

regulator is an asset to systems requiring high relief capability such as welding,

blow molding operations, steel, aluminum, and glass production.

In cylinder applications, this regulator excels in maintaining optimal system

pressure for consistent operating conditions. For instance, in an application

where 100 psi is sent to the regulator, the regulator can be set to maintain a

certain pressure (say 60 psi) regardless of any downstream resistance. Though

the cylinder process may create increased backpressure downstream, the

regulator senses the disparity and adjusts the pressure accordingly. This

consistent pressure helps provides favorable system conditions for high

quality production. Additionally, this high-relief regulator also offers enhanced

ease-of-use because it can be installed in a difficult-to-reach location while its

control regulator is mounted in a more easily accessible location.

Available in 1/4 through 1 1/4 port sizes, the regulator is inline mounted and

utilizes a diaphragm design. It handles a maximum inlet pressure of 400 psig,

outlet pressure of up to 250 psig and has flow rates exceeding 400 scfm. With

the convenience of its full-size relief port, the regulator offers high pressure relief of up to 200 scfm. For flexibility, the regulator is available with an optional pressure gauge and can also be ordered in a non-relieving configuration.

For more information on how the ROSS High-Relief Pilot-Operated Regulator can help you

maintain consistent system pressure in your production operation, contact:

ROSS CONTROLS Customer Service

800-438-7677 (in the U.S.) or 706-356-3708 (outside the U.S.)

E-mail: custsvc@rosscontrols.com

Internet: www.rosscontrols.com

|

|

AutomationDirect extends Pneumatics product line

Cumming, GA, The NITRA line now includes several new series of products to help meet a broad range of pneumatic air supply pressure regulation and filtration applications. While each series is designed to work in stand-alone applications, the modular design enables field assembly for combining additional components.

Cumming, GA, The NITRA line now includes several new series of products to help meet a broad range of pneumatic air supply pressure regulation and filtration applications. While each series is designed to work in stand-alone applications, the modular design enables field assembly for combining additional components.

The AF Series particulate and moisture separation air filters are available with 1/8 to 1-inch NPT female port sizes and either a semi-automatic or automatic drain. Polycarbonate bowls are standard on 1/8 through -inch sizes, while metal bowl guards are provided on through -inch sizes. The -inch and 1-inch sizes feature all-metal bowl construction with sight gauges. Prices start at $11.25.

NITRA AR Series pneumatic air pressure regulators are available with adjustable pressure ranges of 20-130 psi or 7-60 psi. These regulators feature a locking pressure adjustment knob and integral pressure gauge. The AR series prices start at $17.00.

The AFR Series combines particulate/moisture separation air filters and adjustable pressure regulators, all in a single convenient unit. Available in 1/8-inch through one-inch sizes, the pressure regulator features a locking pressure adjustment knob, integral pressure gauge with adjustable pressure ranges of 20 -115 psi. AFR Series prices start at $23.00.

AL Series mist-type air lubricators are available with 1/8-inch to one-inch NPT female port sizes and a lubrication rate adjustment with sight gauge. The -inch and one-inch sizes feature all-metal bowl construction with sight level gauges. AL Series prices start at $12.25.

Replaceable 40 micron filter elements are standard. When stricter filtration is required, an optional, customer-installable, five- micron filter element is available for $1.00.

NITRA ARV pneumatic manual shut-off pressure relief valves are available with 1/8-inch to -inch female ports. The three-way, two-position design is used to shut off upstream pressure and relieve downstream pressure. The manually rotated knob can be locked out with the included padlock. ARV prices start at $19.75.

Three new series of directional control solenoid valves are also available. Solenoid coils for each series are available in either 24 VDC or 120 VAC control voltages. The available single-solenoid models provide two-position, normally closed, spring return operation and double-solenoid models provide two-position, energize open/energize closed operation. DIN-style wiring connectors feature LED indication of solenoid coil status.

AVP series three-way stackable poppet-style valves, starting at $16.75, can be used in individual valve applications or, to simplify piping connections, multiple valves can be field assembled to share supply air.

AVS-3 series valves, starting at $19.75, are body ported three-port (three-way) spool valves with port sizes up to 3/8-inch NPT and flow coefficients (Cv) from 0.78 to 1.67.

AVS-5 series body ported five-port (four-way) spool valves start at $19.75 and are available with port sizes up to 3/8-inch NPT and a flow coefficient (Cv) range of 0.67 to 0.89. In addition, AVS-5 double solenoid models are available with three-position, center closed or center exhaust operation. For multiple-valve applications, AM-5 series manifolds are available in 2, 4, 6 or 8 stations (starting at $9.25).

The complete NITRA line can be seen by visiting: http://www.automationdirect.com/pneumatic-parts.

AutomationDirect sells over 9,500 feature-packed products through its Online Automation Superstore and 2,750-plus-page catalog. The company offers its customers high-quality automation products, which are often priced below the industry average, 24-hour order entry and same-day shipping on in-stock items, outstanding sales and technical support, and a 30-day money-back guarantee on almost every product. For a free catalog, access their Web site at www.automationdirect.com or call 800-633-0405.

|

|

Highly Modular Valve Manifold System from Bosch Rexroth

Series HF02-LG pneumatic valve system from Rexroth with uniform interface

Series HF02-LG pneumatic valve system from Rexroth with uniform interface

Thanks to its high level of modularity, the new HF02-LG can be integrated in a wide variety of automation concepts.

The HF02-LG series from Rexroth rounds out its standardized range of HF valve manifold systems with a weight-optimized base plate valve featuring high flow rates. The dependable HF family is now available with flow rates of 0.4Cv, 0.7Cv, and 1.4Cv and can be actuated with just one bus connection for all series.

The uniform connection technology for Rexroth valve manifold systems simplifies integration of pneumatics in a wide variety of automation concepts. Thanks to its modular design, the system enables use of multiple plugs and connections for all common field buses, with and without I/O signal processing and supports an integrated Drive & Diagnostic Link. The uniform interface for common field bus control (B-design) permits a simple and clear combination of various valve manifold systems, as well as standardized programming.

The new HF02-LG valve manifold system benefits from a free selection of connection technology. With a flow rate of 0.4Cv with a valve width of 20 mm, the system can accommodate up to 16 valve positions in one unit. An exceptionally modular design makes it possible to change the electrical controller without having to disassemble the valve manifolds. Electrical linking with other valve manifold systems, such as the HF03-LG and the HF04-XF, or individual valves, is simple using Rexroth's module extension.

Robust parallel plug connectors in the base plates facilitate conversion of an HF02-LG valve unit and the plug-in valve makes it possible to exchange valve functions quickly and easily. Another special feature is that the customer can convert the pilot from an internal pilot control to an external pilot control directly on the left end plate.

The HF02-LG provides all valve functions: 2 x 3/2, 5/2, and 5/3. Dual-pressure operation is possible using separate exhaust connections for channels 3 and 5. Pressure zones can be limited to one valve. In principle, the valve manifold system has been designed for an internal working pressure of 36 to 145 psi and can be operated in a temperature range of 32 to 1222F. Up to 32 coils can be actuated with the 44-pin D-Sub high-density plug.

Rexroth provides a user-friendly configurator to assist designers who would like to integrate this valve manifold system in their installation. This online tool lets you easily configure valve units with all their accessories and displays them with a pneumatic circuit diagram or dimensional drawing. The latest enhancement: The user can download the configured unit as a 3-D PDF in which the unit can be rotated on the screen and viewed from all sides.

The HF02-LG valve manifold system is ideal for applications requiring a high level of modularity, such as in machine tools, special-purpose machines, welding technology, or polymer processing.

Bosch Rexroth AG is one of the worldds leading specialists in the field of drive and control technologies. Under the brand name of Rexroth the company supplies more than 500,000 customers with tailored solutions for driving, controlling and moving. Bosch Rexroth is a partner for industrial applications and factory automation, mobile applications and renewable energy.

As The Drive & Control Company, Bosch Rexroth develops, produces and sells components and systems in more than 80 countries. In 2009 Bosch Rexroth, part of the Bosch Group, achieved sales of around $5.7 billion (4.1 billion Euro) with 34,200 employees.

For more information please visit: www.boschrexroth-us.com/brp

|

|

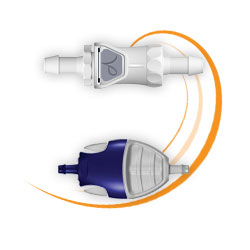

Value Plastics offers two distinct families of quick connect fittings

Value Plastics offers two distinct families of quick connect fittings (quick disconnect couplings), the XQC Series - Thumb Latch Quick Connects and SBL Series - Side Latch Quick Connect products, for applications covering 1/88 (3.2 mm) through 3/88 (9.5 mm) ID tubing.

Value Plastics offers two distinct families of quick connect fittings (quick disconnect couplings), the XQC Series - Thumb Latch Quick Connects and SBL Series - Side Latch Quick Connect products, for applications covering 1/88 (3.2 mm) through 3/88 (9.5 mm) ID tubing.

XQC Series - Thumb Latch

XQC Series products are produced in acetal and polypropylene in five basic configurations in-line male, in-line female, male panel mount, female panel mount and elbow, available in open flow and with integral shutoff valves, bring performance, convenience and utility to your tubing applications. Offered in three tubing sizes to fit 1/4" (6.4 mm), 5/16" (8 mm) and 3/8" (9.5 mm) ID flexible tubing, XQC series products may be used with PVC, polyurethane, silicone and other types of flexible tubing. 700 Series single barbs provide increased pulloff resistance when compared to three-barb styles. For versatility, durable XQC Series couplings interchange with other plastic and thumb latch couplings. Bring performance and service to your tubing applications by specifying XQC Series quick connect fittings.

SBL Series - Side Latch

Value Plastics introduces a new concept in quick connect fittings for fluid management applications. The SBL Series connector system is so intuitive that users just automatically know how to operate it the minute they pick it up. SBL Series quick connect fittings are cost effective and designed to meet your needs for a reusable component for small-bore applications in all fluid delivery areas. Contact us today for free samples and make this exciting new fluid link part of your next design.

The SBL Series range is available in nylon, in two contrasting colors and fits 1/88 (3.2 mm) and 3/166 (4.8 mm) ID tubing, for in-line applications.

Value Plasticss, Inc.

3325 Timberline Road

Fort Collins, CO 80525 USA

Phone: (970) 267-5221

Fax: (970) 267-2064

|

|

New Centric Grippers with Multitooth Guidance Gripper

PZB-plus is a newly designed series of 3-finger centric grippers, whose special feature is a central bore designed as a sleeve. This central bore, which is also equipped with female threads for customer-specific add-ons, can be used to supply material or as an ejector. However, it can also be used to monitor the handling or assembly process with a camera system or to pick up workpieces and centre them using the sleeve during the gripping process, for example. There are also threads integrated on the upper face of the gripper in addition to the threads on the cover plate, to facilitate mounting customer-specific add-ons.

PZB-plus is a newly designed series of 3-finger centric grippers, whose special feature is a central bore designed as a sleeve. This central bore, which is also equipped with female threads for customer-specific add-ons, can be used to supply material or as an ejector. However, it can also be used to monitor the handling or assembly process with a camera system or to pick up workpieces and centre them using the sleeve during the gripping process, for example. There are also threads integrated on the upper face of the gripper in addition to the threads on the cover plate, to facilitate mounting customer-specific add-ons.

PZB-plus is available in two different stroke length versions, whereby the smaller stroke results in approximately double gripping force. The six sizes from 64 to 200 are fitted with a multitooth guide, as is the case in the premium series PGN-plus and PZN-plus. Therefore, compared with the older PZB classic series, PZB-plus can handle 100 percent higher torques in directions at right angles to the gripping motion. This makes it possible to use smaller grippers than before, and thus to work more economically.

An optional gripping force safety device is also available for PZB-plus, which are spring loaded for ID or OD gripping. The position is monitored either via a magnetic switch or inductive proximity switch, and the hose-free direct connection makes assembly and installation significantly easier.

The comprehensive and sophisticated accessories available for the other plus series will of course also be available for the PZB-plus series. This includes force measurement jaws, quick-change jaws, valves, sensors or jaw blanks.

Donnt miss out on what SCHUNK has to offer at IMTS 2010!

Visit us at Booth W-2000 for all your Automation needs.

About SCHUNK:

SCHUNK is a family owned operation and a global player in one. Totaling more than 60 years of experience, SCHUNK is a leading worldwide manufacturer of toolholding components, workholding systems, and automation components. With their reputation for high quality products, absolute precision, and continuous innovation, SCHUNK is a reliable partner for their customers. For more information, visit www.schunk.com

|

|

Fabco-Air is happy to announce another new product: The FKHT Series Toggle Type Grippers

These grippers are ideal for heavy workpieces.

These grippers are ideal for heavy workpieces.

A toggle mechanism holds the workpiece securely even if the pressure drops.

The addition of optional sensors enables both "open" and "close" position

sensing.

Additional features include:

Magnetic piston is standard

Gripper body is hard coated aluminum ensuring abrasion and corrosion

resistance

Tapped mounting holes on 5 surfaces

No extra lubrication required

Catalog FKHT-10 can be downloaded at:

http://www.fabco-air.com/pdf/FKHT_toggle_gripper_web.pdf

The bulletin is also available on our literature request form, as well as our

main catalog download page.

Please contact Fabco-Air, Inc. customer service with any questions.

Still don't see what you want? No problem. Fabco-Air has a fully equipped

machine shop and staff of engineers ready to help you build the special

solution you need, so you can build the business you want.

Submit a Request for Quote today!

Contact Information

phone: (352) 373-3578

fax: (352) 375-8024

email: service@fabco-air.com

|

|

![]()

![]()